While effective to a certain extent, silicone itself lacks impressive thermal conductivity, and the paste may deteriorate over time, reducing its effectiveness.

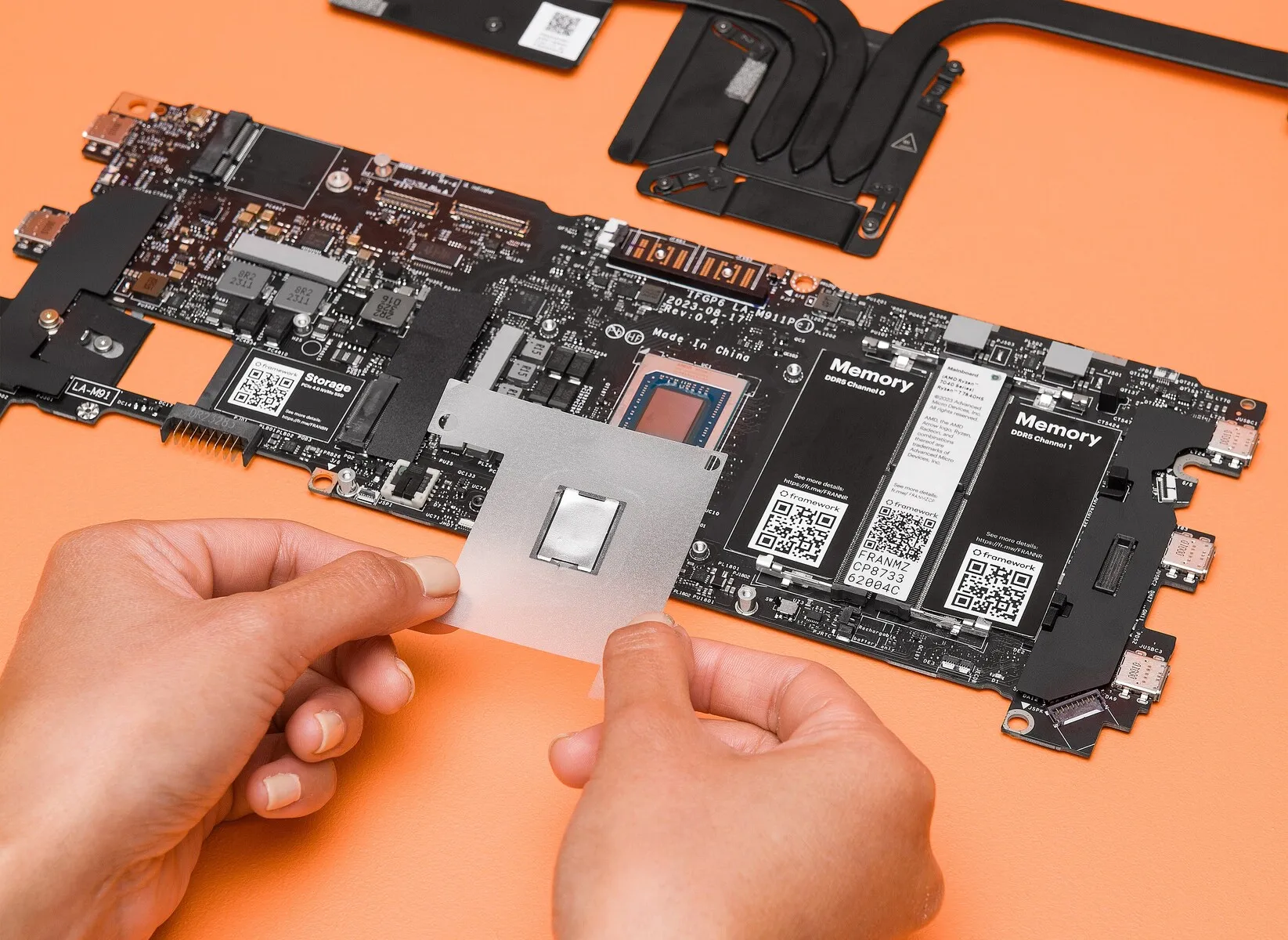

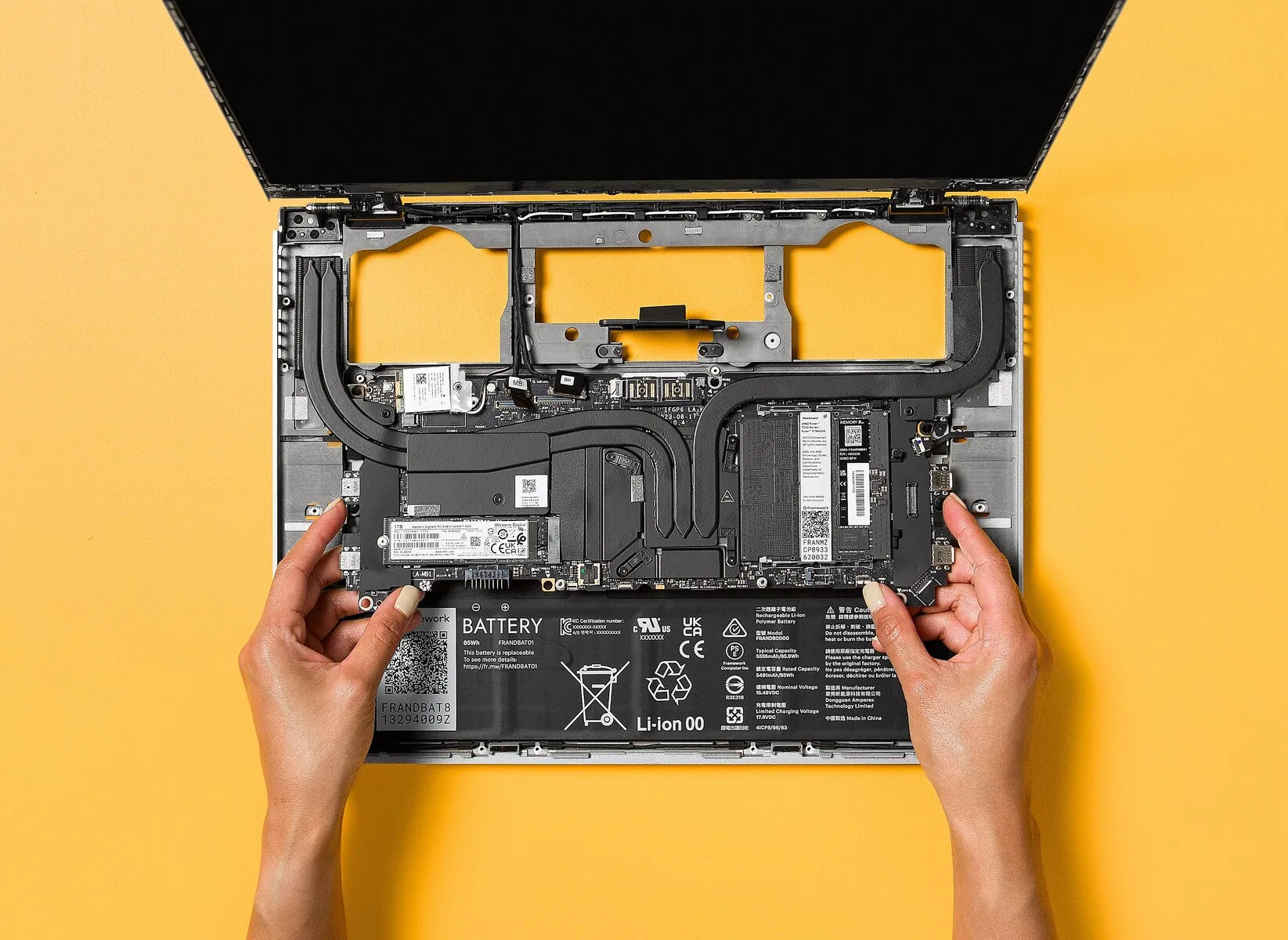

In contrast, the Framework Laptop 16 employs a liquid metal thermal interface on the CPU. Liquid metal, composed entirely of indium, tin, and bismuth, undergoes a phase change from solid to liquid at approximately 58°C as the CPU heats up, thus seamlessly filling any gaps. Being a metal, it exhibits exceptional thermal conductivity, boasting a rating of 72 W/mK, a significant improvement over the 5-10 W/mK typical of traditional thermal paste. Moreover, liquid metal does not suffer from issues like drying out or diminishing performance over time. Our chosen liquid metal solution is sourced from Coollaboratory's Liquid MetalPad, in collaboration with their Taiwan-based partner, CCHUAN.

Concerns may arise regarding the safety of having highly electrically conductive liquid within a portable device. In this context, our design encompasses multiple safeguards. Firstly, small capacitors adjacent to the CPU dies prompt us to apply an insulative glue layer during the Mainboard assembly process. Secondly, an etched pattern on the vapor chamber's surface retains the liquid metal through tension. Finally, a dual foam barrier, situated between the processor package and the vapor chamber copper plate, effectively seals the CPU, preventing any escape of liquid metal. This comprehensive approach culminates in an exceptionally efficient thermal solution, ensuring outstanding CPU performance and reliable operation.

Source: Framework Blog