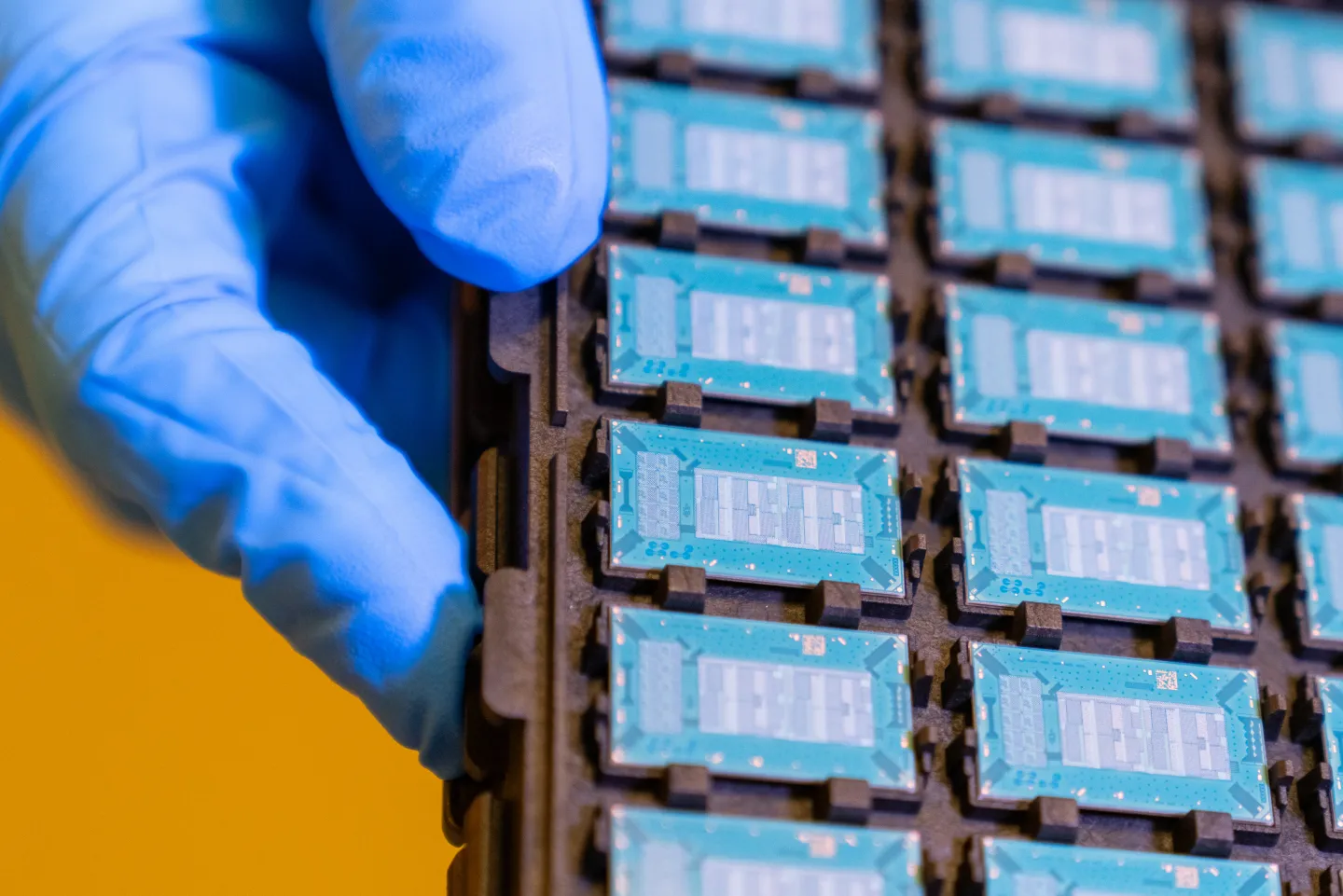

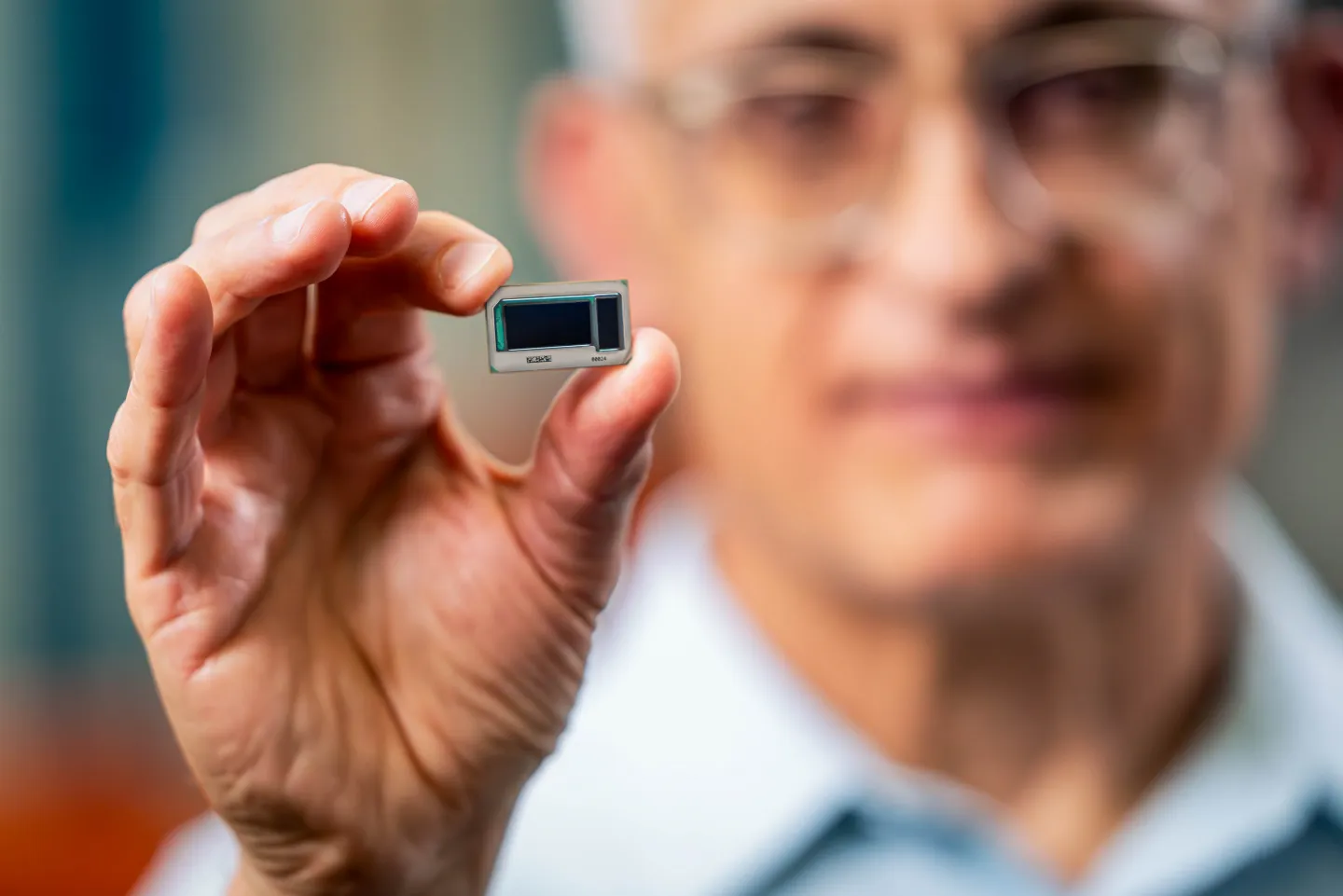

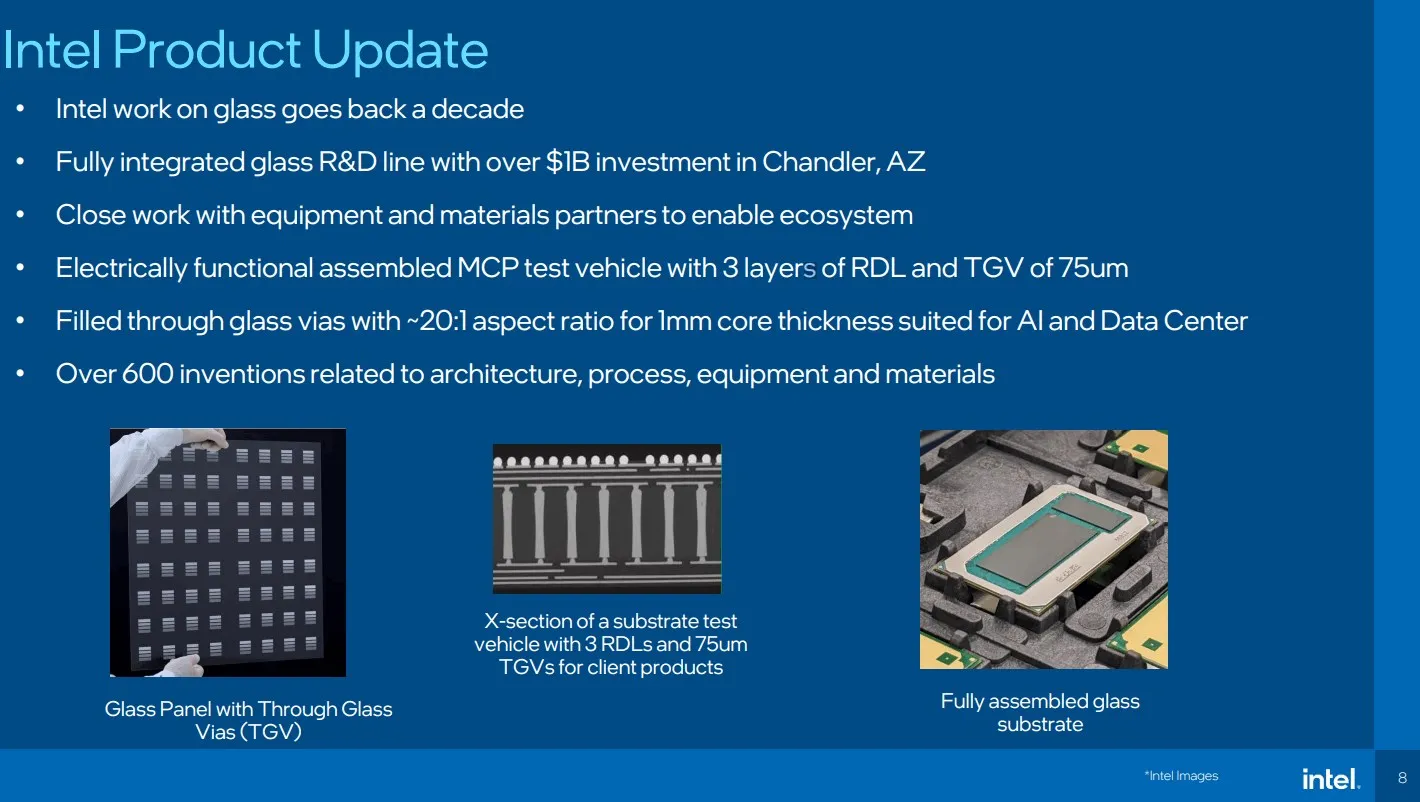

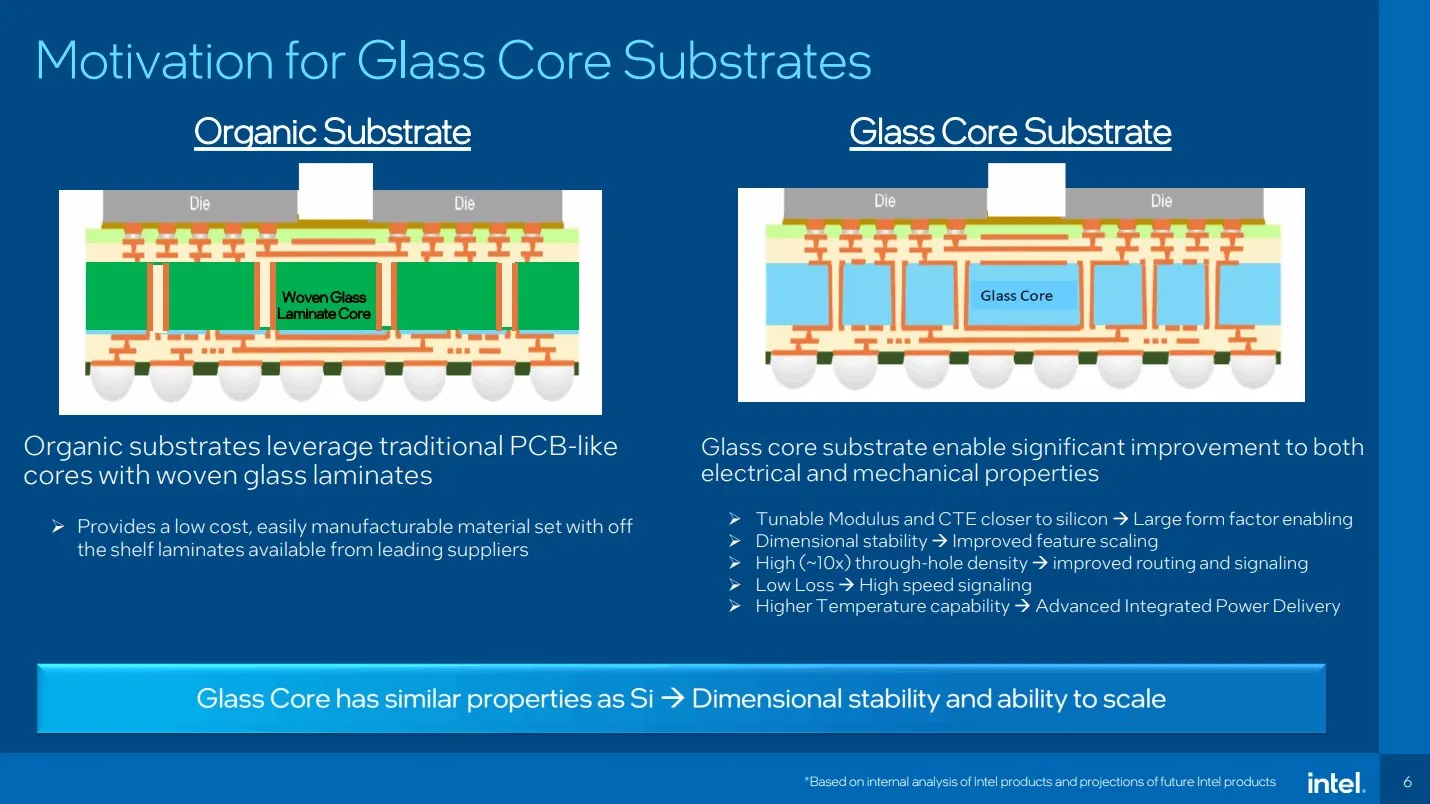

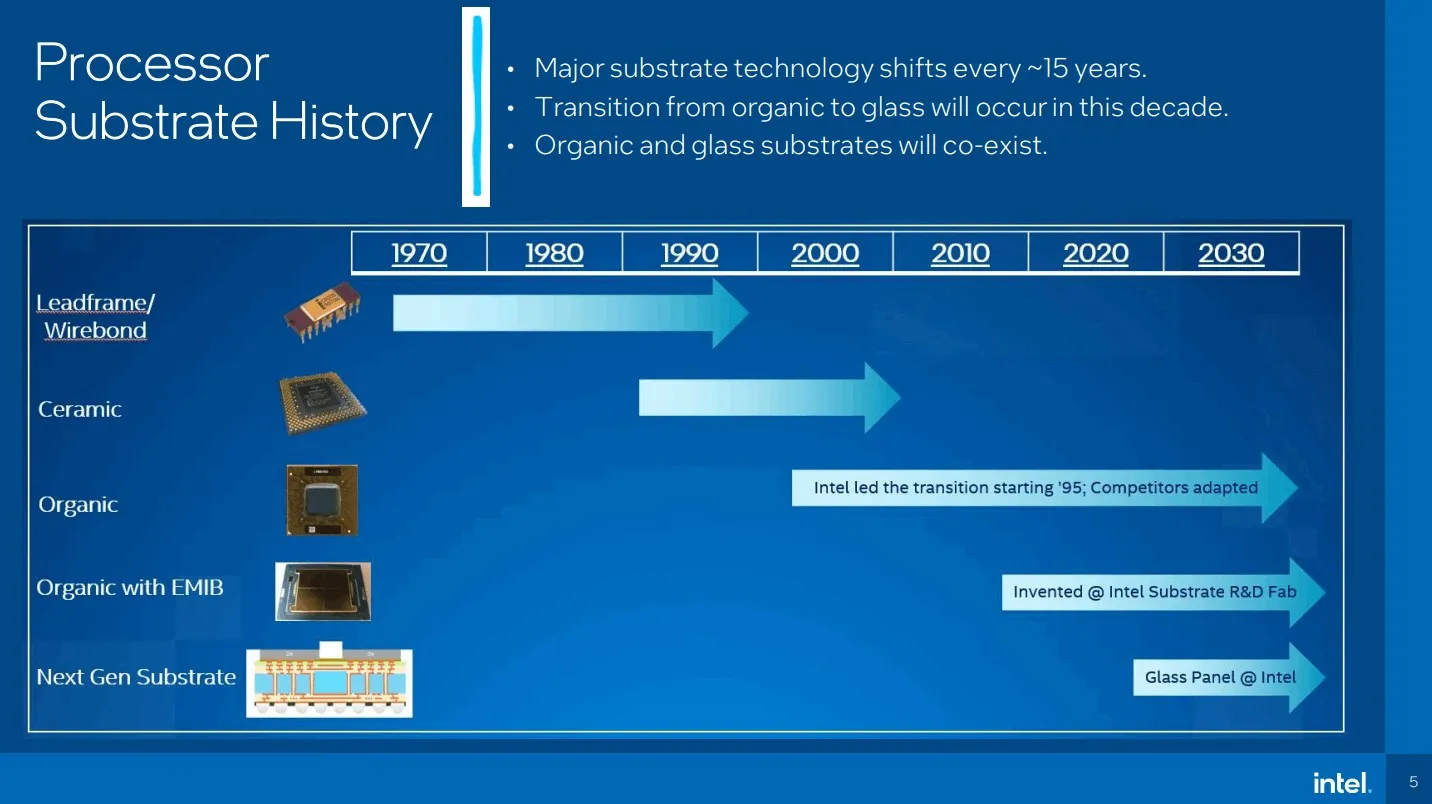

Intel is transitioning from plastic to glass as the base material for its computer chip layers to improve processor capabilities. This shift allows for the integration of more chiplets and increased electrical interconnections on Intel's processors. Glass possesses improved resistance to high temperatures, which ensures better chip stability during production.

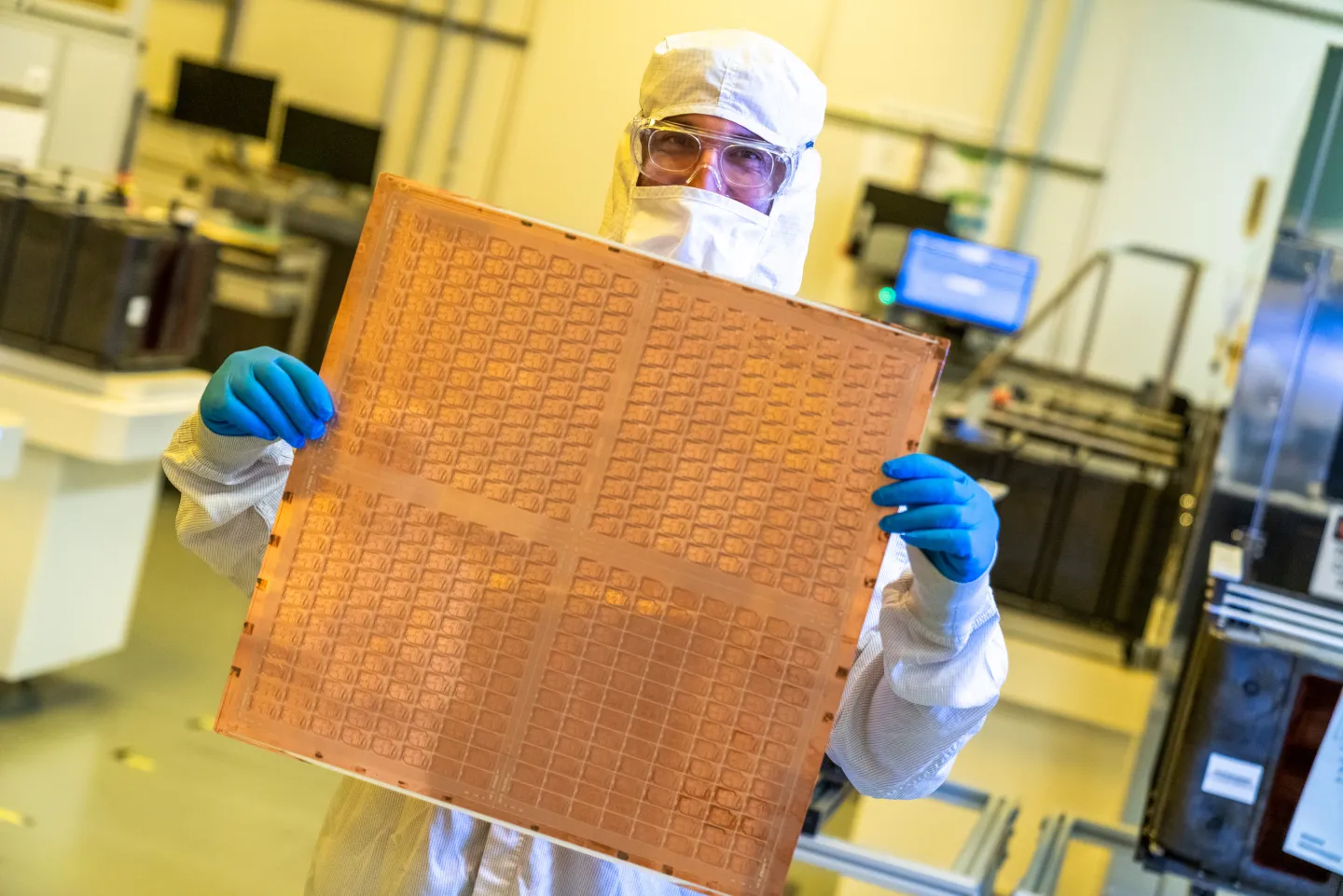

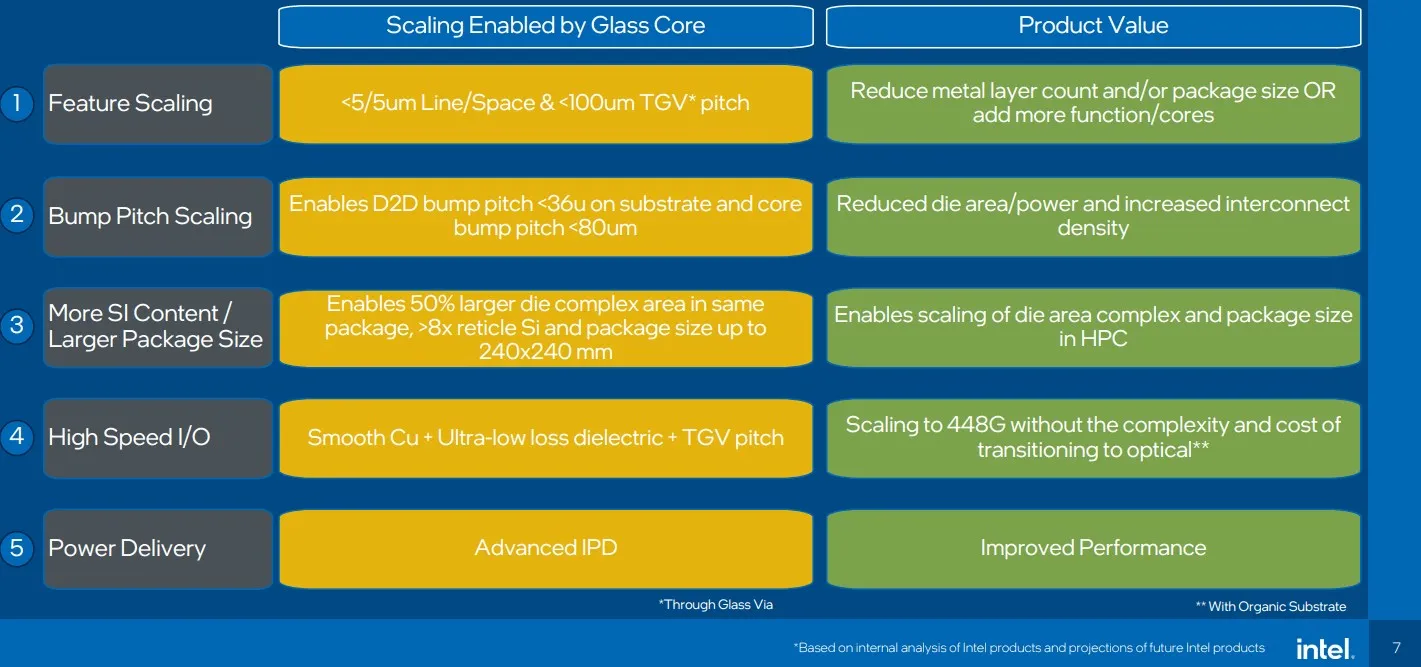

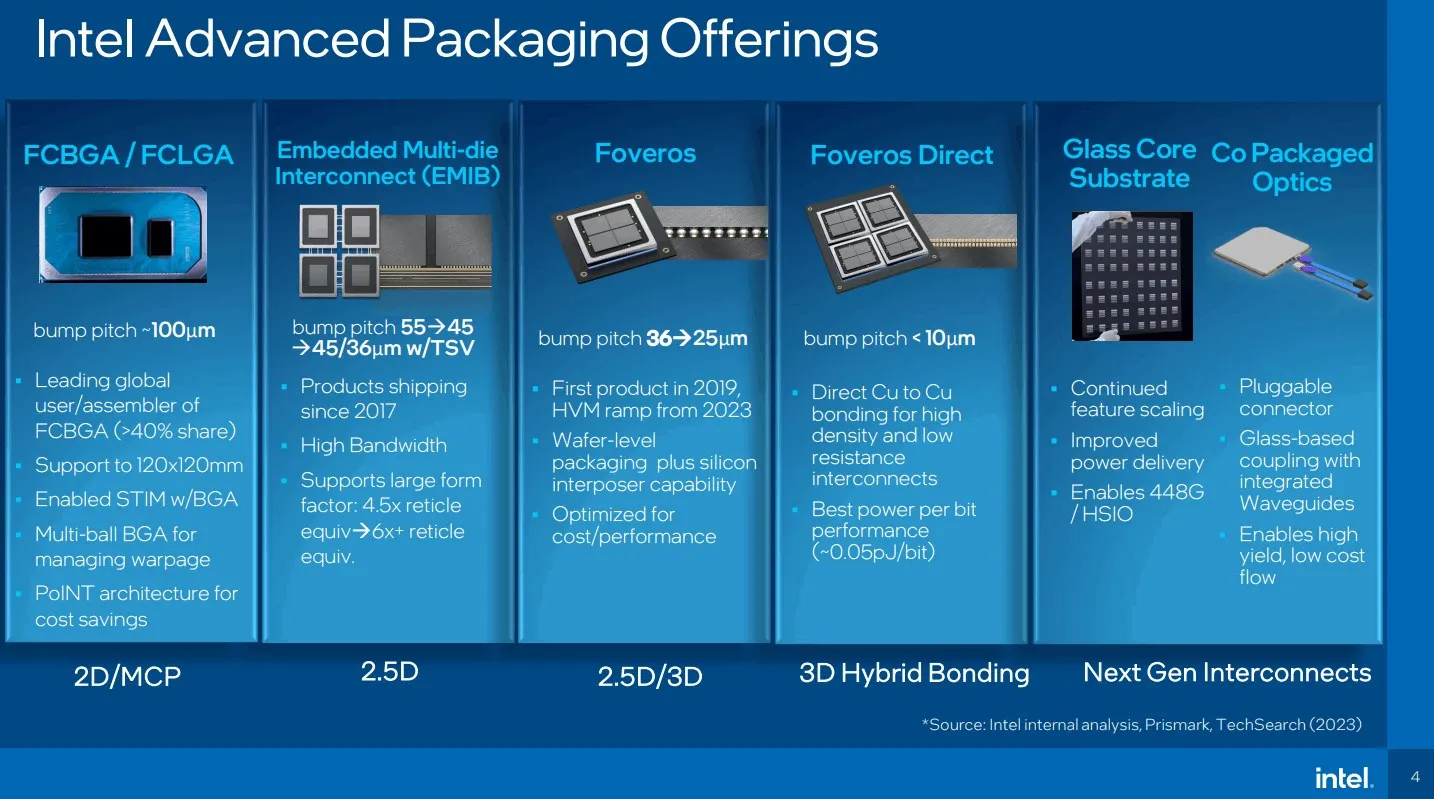

Rahul Manepalli, Intel's Director of Substrate TD Module Engineering, recently emphasized the importance of this development in a press briefing. Since their initial announcement, Intel has provided more details about its research on glass-based substrates. The material offers several advantages over current PCB-like materials, suggesting its suitability for upcoming chip designs. Intel plans to release products based on this technology between 2025 and 2030. The use of glass allows Intel to design larger chiplet assemblies and achieve up to 10 times the electrical interconnect density. For example, the glass material permits the accommodation of a die that is 50% larger than its plastic counterpart. This shift could lead to decreased chip manufacturing expenses and higher production yields. The glass substrate also results in a 50% decrease in pattern distortion.After a decade of research, Intel has integrated this technology at its Arizona facility.

Other corporations are investigating glass substrates too, so Intel isn't the sole entity exploring this avenue. However, Intel's adoption of the glass substrate could improve its competitive position. The glass substrate combines a high resistance to temperature, 50% reduced pattern distortion, and a flat surface, potentially offering up to a tenfold increase in interconnect density over existing organic materials. Such properties allow chip designers to incorporate more chiplets in one package, reducing both power consumption and production costs. The robust mechanical characteristics of pure glass also permit the creation of larger package sizes while retaining high production yields. While Intel hasn't specified all applications, potential uses could be in areas like data centers, AI, and graphics.