It is always funky to see what a device initially is costing to produce with the knowledge that you know what you pay for in the stores. The Galaxy S5, Samsung’s new flagship smartphone, costs about $256 to build according to a teardown analysis by market research firm IHS. The device sells for $660 without a contract, implying a gross margin for Samsung of about 60 percent.

Samsung declined to comment on IHS’ findings.

The cost of components, known in electronics industry lingo as a bill of materials, has been drifting upward on Samsung phones in recent months, said Andrew Rassweiler, an analyst who heads up IHS’ teardown research efforts. “Our main takeaway is that Samsung has been moved up to the higher end of the cost spectrum. It used to be that its typical flagship phone sold for $600 without a contract and had a bill of materials of about $200,” Rassweiler said. “Now they’re inching up above $250 regularly.”

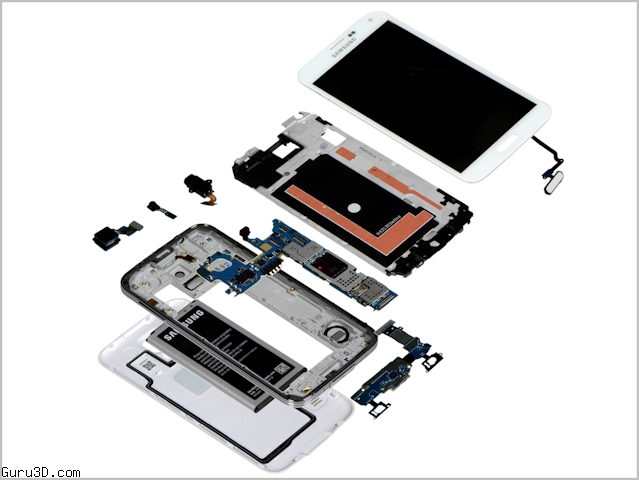

And despite the S5’s place atop the Samsung smartphone line, Rassweiler said that aside from its ability to survive getting wet, there’s not much else extraordinary about the phone, at least internally. “Inside we see mostly a lot of recycled components that we’ve seen before. There’s really nothing special inside where Samsung is pushing the envelope,” he said. “There’s no breakthroughs, there’s nothing earth-shattering. It’s really just a continuation of what has come before.”

The most expensive component is the display module, which IHS estimates cost about $63. It’s a five-inch display and one which Samsung has used before, Rassweiler said. Samsung also supplied its own memory chips — DRAM and flash memory — at a combined cost of $33.

The main chip inside the phone is a Qualcomm Snapdragon 801. It’s a chip that has been seen in many other phones of recent vintage from Nokia and LG, though the version used in the S5 is slightly faster than prior generations, Rassweiler said. “We’ve seen a plethora of phones with that chip,” he said.

The S5 also contains a fingerprint sensor that costs about $4, Rassweiler said. This is the same one that Re/code’s Walt Mossberg said failed often for him in his tests. It wasn’t immediately clear what company supplied it, Rassweiler said. But it’s significantly less expensive than the fingerprint sensor seen in Apple’s iPhone 5S. That sensor cost about $15, according an IHS teardown of that device conducted last year. Apple’s flagship cost about $199 to build.

While most smartphones including Apple’s iPhone routinely contain an accelerometer, a gyroscope and a compass, all intended to detect and measure the phone’s movement, the S5 also contains a biosensor that is capable of measuring personal health data. One use of the sensor is to allow the phone to work with Samsung’s Gear Fit line of wearable activity monitors.

Made by chipmaker Maxim, the sensor adds about $1.45 to the component cost. Maxim also supplies power management chips in the S5 that in previous devices have been supplied by Qualcomm. “If there’s a winning supplier with this phone, it’s Maxim,” Rassweiler said.

The cost estimate includes hardware and the estimated cost of assembly, which IHS pegs at about $5 per unit. It doesn’t include the cost of software, distribution or marketing.

Samsung’s Galaxy S5 Costs About $256 to Build