Robert has developed a kinetic custom PC case, a project combining woodworking, 3D-printed components, and acrylic materials to create a dynamic and interactive computer case. The design features moving parts visible on the front panel, driven by a system of gears and shafts housed within a wooden exterior.

The project began with the modification of a Corsair Crystal 570X PC case. Robert removed the original glass panels and used the frame as the foundation for his build. He constructed a new exterior from plywood, incorporating hexagonal cut-outs for aesthetic and functional purposes. This external shell, predominantly black with wooden features, is designed to enclose the 570X chassis. For panel attachment, he employed a pressure-fit method, avoiding traditional fasteners or magnets.

AKinetic Core:

The centerpiece of the case is an Arduino Uno board, programmed with various code snippets. This board controls a 4988 stepping motor and a Nema 17 motor, responsible for the kinetic movements. After extensive testing and adjustments, the system was integrated into the case, drawing power directly from the computer's motherboard.

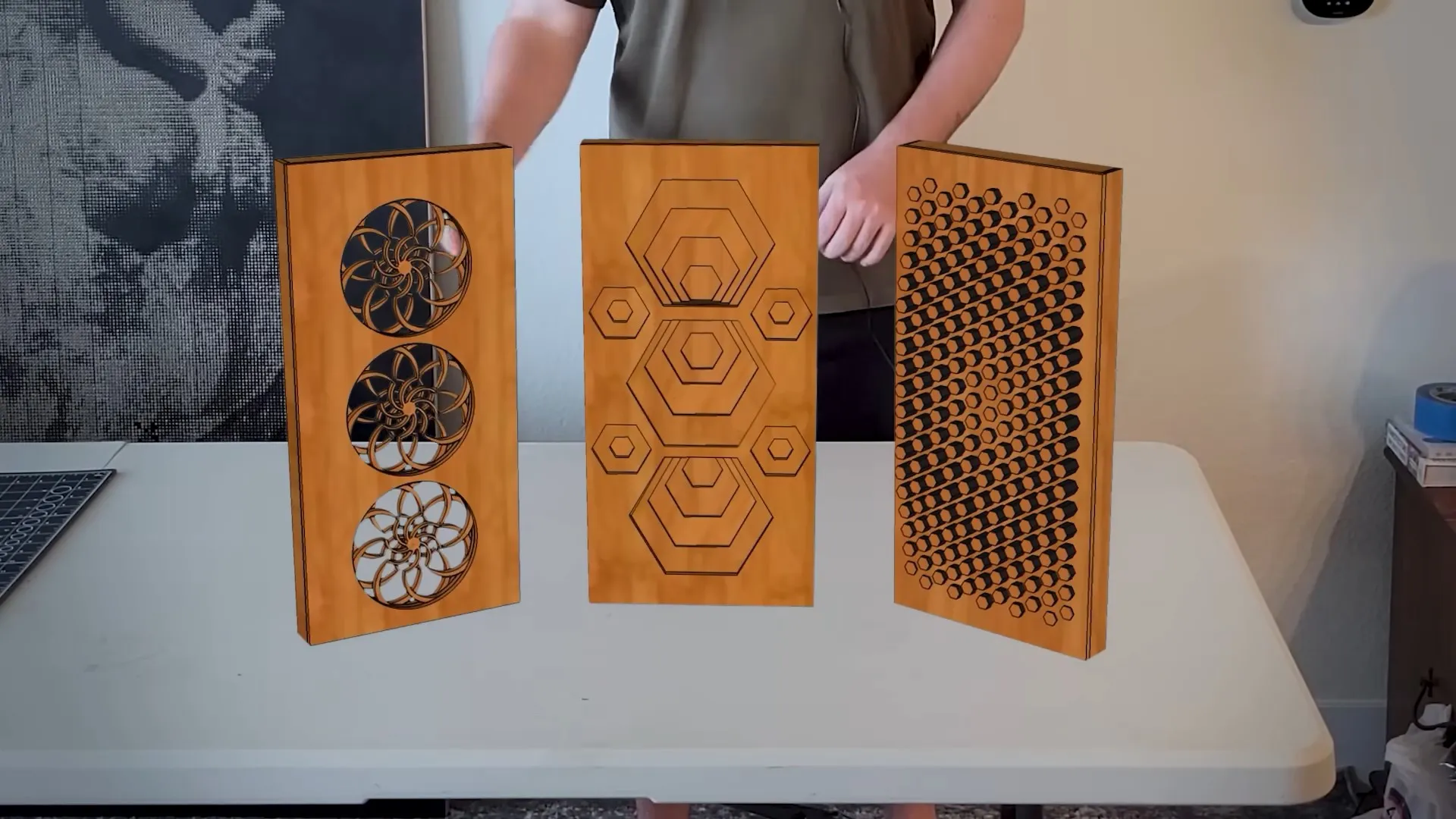

Robert undertook the challenge of creating three different kinetic front panel designs, each with increasing complexity. These panels are modular, allowing for interchangeable configurations. The designs are engineered to ensure adequate airflow through side openings.

First Design: This initial design includes three interlocking circles resembling a stained glass rose window. The internal frames, connected to the Nema17 motor, move in sync with the gear system. The combination of wooden gears and 3D-printed components ensures smooth motion.

Third Design: Skipping the second iteration due to its complexity, Robert focused on the third design, which involved assembling 885 parts, including 214 3D-printed elements. This created a complex, synchronized motion across the front panel's hexagonal sections.

Precision and Detail: To achieve seamless movement, every component was meticulously sanded. Black vinyl was applied for smoother operation. The combination of 3D-printed parts and acrylic gears was crucial in realizing the desired kinetic effect, particularly given the challenges of working with laser-cut acrylic.

Inspiration and DIY Spirit: The concept was inspired by Cyberpower's unreleased Wild Kinetic series cases. Despite the absence of these cases in the market, Robert was motivated to create his version. His project underscores the value of DIY endeavors in personalizing and crafting unique computer cases, beyond what is available commercially.

Conclusion: Robert's kinetic PC case project is a testament to the merging of technical skill, creativity, and personal vision in the realm of custom PC case design. It illustrates the expansive potential for individualized and innovative approaches to computer hardware aesthetics and functionality, setting a new standard in PC case customization.

Source: via toms hardware