Article

Deep and optimal liquid cooling for AMD ZEN2

An Overview of EK-Quantum Magnitude - an article written by 1USMUS

Today 1USMUS brings you an article that goes a little deeper into liquid cooling, who most of you guys know him as he is the programmer behind the DRAM calculator, as well as an old-timer here on the website. While the topic title doesn't cover what we're showing in this article, it's self-explanatory really. This article covers the Evolution of EK water blocks and optimal water block choosing for AMD processors on Zen 2 microarchitecture, including an overview of EK-Quantum Magnitude. If you are planning some serious liquid cooling on your ZEN2 processor, definitely read this article.

Introduction

We live in a unique time where the race of silicon process technology and performance has reached a new boiling point. 10’s cores, hundreds of megabytes of L3 cache, 5GHz, and other decisive factors make fans of both camps face off again and again on CPU forums, proving who has the coolest overclocking results in benchmarking. A simple user who wants to do something like this by getting into this vortex just starts to get lost from the amount of advice and opinions. Of course, every idea and every view has a certain right to exist, but not today it will be about that. We want to discuss the roots of cooling problems and a modern solution with you, using the example of the EK water block range. In particular, we will discuss how to cool hot but economical (in 2019 it happened) processors Ryzen third-generation (Zen 2).

As many of you know, the processor in a cross-section resembles a sandwich: it consists of a textolite, a "bridge" by means of which a crystal connects to the socket, the crystal itself and, of course, the thermal interface which takes all the heat shock on itself. The other important information that you may not have taken into account is the heat dissipation relative to the area of the crystal in the processor. Of course, with TDP unchanged, a smaller chip area will cause more problems for absolutely any cooling system (we are not talking about chiller and liquid nitrogen). As for the numbers, we have the following data available:

- Ryzen 7 2700X with a crystal area of 213mm2 and TDP 145W has a thermal flow of 0.68 W/mm2;

- Core i9-9900K with an area of 174mm2 and TDP 200W - 0115 W/mm2;

- Ryzen 7 3800X with 74mm2 CCD and 90W TDP (not including IOD) - 1.21 W/mm2;

- Core i9-10900K with 198mm2 area and TDP 250W 1.26 W/mm2.

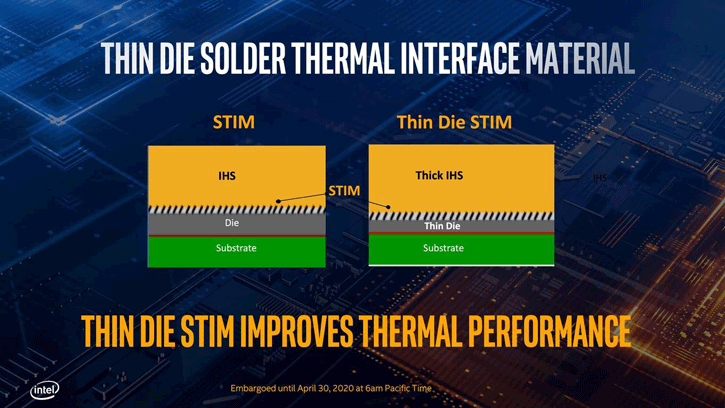

We can see that the latest generation of Intel and AMD processors have significantly increased the readings of the released heat flow relative to the area and something must be done about it because the further transition to a finer process will only exacerbate the situation, especially when you realize silicon is not a good conductor of heat. For example, the thermal conductivity of silicon is 149 W/(m-K) and that of copper is 401 W/(m-K). Intel has found a way out of this situation. Three weeks ago the Comet Lake processor line was presented, an interesting feature of which is a "shortened" top layer of silicon substrate and a concurrently enlarged layer of thermal interface, which is under the processor cover.

On digits it looks more interesting, Coffee Lake has a thickness of silicon substrate of 800 microns, and for Comet Lake-S processors it has decreased to 500 microns. The difference is almost 38%, which definitely works out for them as it can yield 5.4GHz for all 10 cores in-home use without any chillers. For simple users, this innovation allowed us to see lower temperatures that can not, not please. As for further potential, additional "grinding" is still possible.

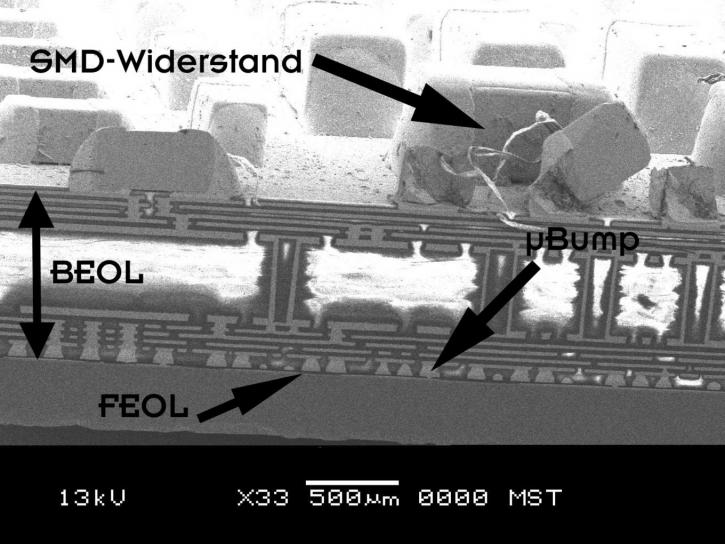

Since the BEOL layer is still impressively thick and the only limiting nuance is the technology of this very "grinding", because at the border of FEOL and BEOL are our transistors. Next page, please where we'll discuss how AMD is tackling all this.