Thermal Internal - AMD

Thermal Internal - AMD

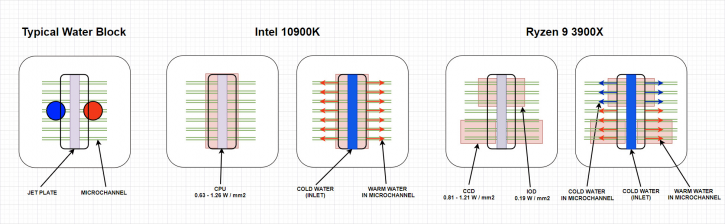

What about AMD? At the moment we have only one 7nm generation release, which has already proved to be a very energy-efficient solution but at the same time hot for quite primitive cooling systems, whether it's maintenance-free water or a direct-contact cooler. I propose to consider this in more detail, particularly the maintenance-free water block. It consists of a heat distribution copper plate (sometimes nickel-plated) in which there are slots (internal radiator) and the pump itself. In most cases, the waterblock “chamber” has a very small area of micro-channels and does not cover half the area of the processor IHS. In the illustration it often looks like this:

At a glance, the active waterblock chamber covers both IOD (IO chip) and CCD (processor cores), but we often overlooked physics, the heat is not distributed vertically upwards, but evenly in all directions relative to the emitter (at the moment we do not take into account that prevent this uniform distribution of heat will be other surrounding materials that have their own weight and heat conductivity). For this reason, we need to remove heat from the entire processor cover (IHS) as it plays the role of a heat distributor. Ideal would be a significantly enlarged waterblock chamber with micro-channels:

Fortunately, there is such a product in the line of water blocks from EKWB, and today we have the opportunity to compare theory with practice, whether it gives an advantage and if so, what it is.

The last and perhaps the most important feature of which should have a water block is the efficient use of all micro-channels and water flow respectively. Let's consider an example of using a typical cheap water block on processors of both camps.

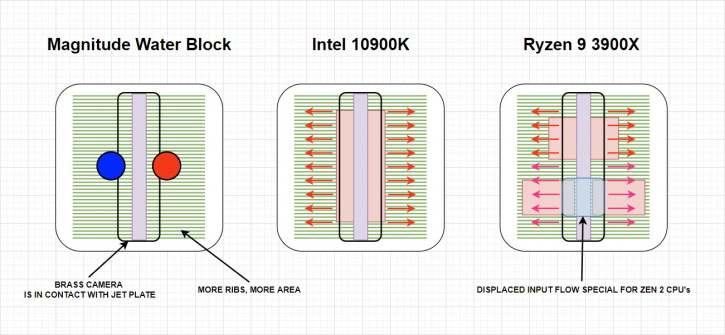

The first thing that catches your eye is the orientation of the CPU crystal(s) and, accordingly, the transverse position of the micro-channels relative to the crystal. If microchannels are longitudinal - 1/2 of the stream will be used suboptimally, in particular, aggravation of the situation will be observed on two-chip Ryzen, where 1/2 microchannels (and 1/2 stream) account for 2 serious heat sources. From here it follows that the waterblock created for Intel processor (before Zen 2 output there were no other variants simply) is not able to work with maximum efficiency according to some physical laws, although it will certainly work as the heat spreads in all directions depending on the thermal conductivity of materials surrounding the source of heat and solder under IHS processor, which is also a kind of heat distribution plate. An exception may be a waterblock with a massive copper heat exchanger, which in turn works as a "sponge" of heat, or a waterblock with a brass (or copper) chamber and a displaced input stream, which will strike at the location of the CCD's. A striking example of this design is our EK-Quantum Magnitude.

In the case of Intel, we do not see any special magic, but with Ryzen we can see that a concentrated flow of cold water beats at the intersection between two CCDs and creates additional pressure in the micro-channels (marked with purple arrows).

Sounds good, but we did find a nuance that also affects the result to some extent, because due to the small mass of the IHS processor in the case of Ryzen is not evenly heated, streams that go through the IOD (~20W) have low efficiency and just hit the OUTLET port. Perhaps, this nuance was left for the future generation of water blocks, because further development of water blocks has almost reached the point where there is nothing to improve anymore and you need to develop a completely different way of cooling processors. And now let's get to know the guest of honor more closely.